In 2014, we launched MOUSE (Memorable, Outstanding, Unique, Service Experience), a unique customer service-driven initiative. Each month, we focus on a different person or department to find about how that part of the business contributes to the performance of the Group as a whole.

This month we look at PTSG’s London-based Access & Safety team and how, over the last few years, it has played a key role in the capital’s changing skyline.

The capital is forever changing and growing; it now comprises commercial, residential and mixed-use developments alongside historic structures such as St Paul’s Cathedral and Westminster Abbey. The resulting juxtaposition has created a skyline that is unlike that of any other city in the world.

Every new skyscraper must incorporate an access system to allow regular cleaning and maintenance to be carried out. To be called a skyscraper, a building must be more than 14 storeys high. PTSG has great experience and expertise in designing and installing access systems – cradles or building maintenance units (BMUs) and has worked on some of London’s tallest and most recognisable new skyscrapers.

[one_half padding=”2px 2px 2px 2px”]

Leadenhall Tower – “The Cheesegrater”

Using multi-dimensional building information modelling (BIM), PTSG provided two telescopic building maintenance units, with several bespoke cradles ranging from 3m to 9m and the capacity to lift glass up to 2000kg. The 3D model of the BMU combines key information for the ongoing maintenance and life cycle of the systems resulting in the lifting and assembly installation being completed within six days.[/one_half][one_half_last padding=”2px 2px 2px 2px”]

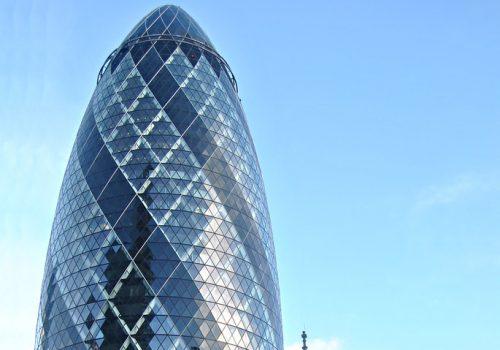

30 St Mary’s Axe – “The Gherkin”

Innovative access equipment was designed, manufactured and installed for the prestigious Norman Foster designed building in the centre of London. Among the many features are a lifting table and hydraulic arm installed below the restaurant floor on level 40, three suspended trolleys and platforms and a rescue trolley hidden away in a garage on level 36. These emerge only when required, navigating the circumference of the building on an exterior track.[/one_half_last][one_half padding=”2px 2px 2px 2px”]

52 Lime Street – “The Scalpel”

At this commercial skyscraper there are three levels of roof plant space, levels 36 & 37 being enclosed and 38+ within the roof attic. PTSG’s expert engineers were called upon to design and install the two complex BMUs, as well as a series of intricate moving roofs to house them, at The Scalpel (52 Lime Street), which enable the safe and easy storage of this access equipment.[/one_half][one_half_last padding=”2px 2px 2px 2px”]

One Blackfriars Tower – “The Vase”

PTSG created three building maintenance units, which were fitted to integrate with the building’s moving doors – also designed and supplied by PTSG – to carry the intricate cladding panels and mask the garage area. This allows the BMUs to be concealed without any visual sign of the systems.[/one_half_last]

Kevin Walton, Managing Director of PTSG’s London-based access solutions provider, said: “I began my career working overseas in Hong Kong and then for Canary Wharf Group building high rise towers. I started my own business, Integral Cradles, in 2004 which was acquired by PTSG in 2015.

“My team of highly professional, creative and talented engineers and designers deliver bespoke access solutions on some of the most technically challenging and iconic projects in the UK. The most important part of my job is ensuring the coordination of the team, our Madrid factory and key supply chain so that we exceed the expectations of our clients.

“What I really love about the job that I do is creating a team mentality and being part of the team as we succeed together. The challenges that we face are working out the best route to complete a task and then staying focused to achieve this goal.”