What’s the Difference?

Electrical earthing and power earthing systems also known as grounding, are both processes that connect an electrical system to the ground for safety and functionality.

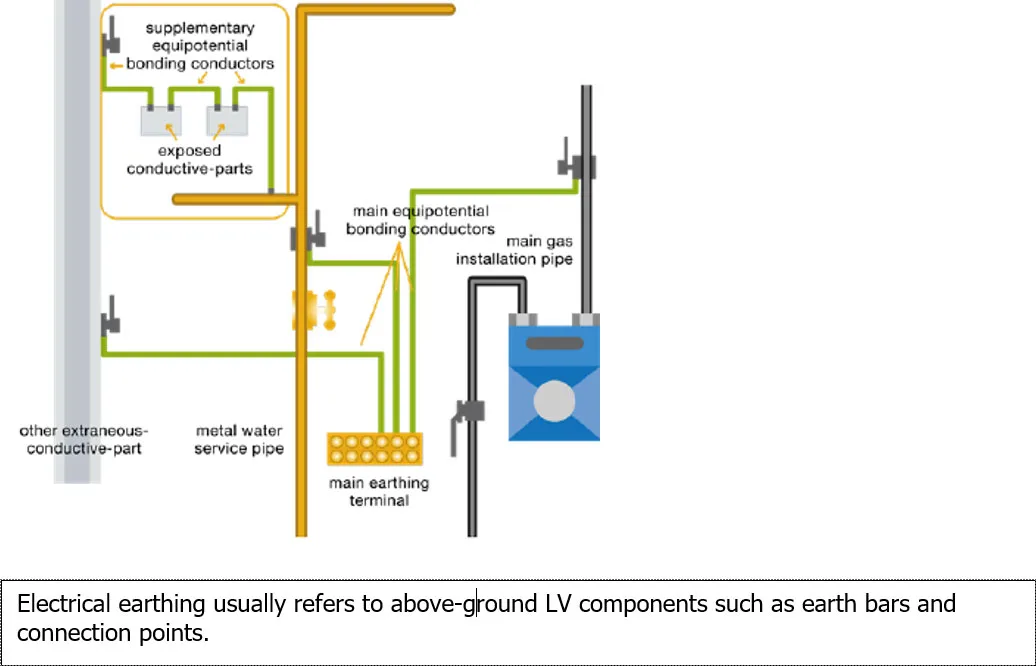

The main difference between the two is that electrical earthing usually relates to anything above ground such as circuit protective conductors and equipotential bonding.

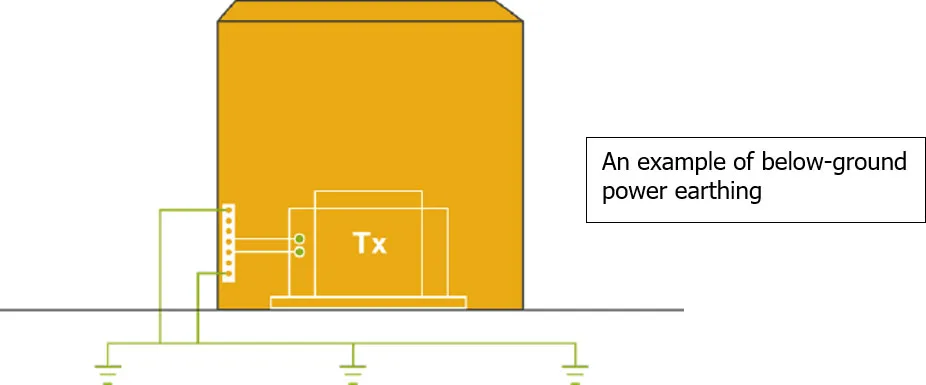

Power earthing (also known as grounding or earthing) relates to the process of connecting electrical systems to physical earth via a network of vertical and horizontal earthing conductors installed below ground.

Did You Know?

Most standard high voltage annual inspections do not include a comprehensive test or inspection of the power earthing system. These systems are vital for the safety and effectiveness of your electrical network, providing a safe path for fault currents and helping to prevent equipment damage and, most importantly, protect personnel from electric shock.

Why This Matters

Over time, your power earthing system can deteriorate or become compromised due to factors like soil conditions, corrosion, or equipment upgrades. Without proper testing, these issues can go unnoticed, putting your infrastructure and team at risk.

Is Your Site Compliant with the Electricity at Work Regulations 1989?

Power earthing systems play a critical role in maintaining site safety – protecting personnel, equipment, and your entire facility from unexpected electrical faults. Such systems should be inspected and tested at regular intervals to remain compliant.

Employers and business owners have a legal responsibility under The Electricity at Work Regulations 1989 to protect employees from threats arising from faulty electrical wiring and installations.

As the last line of defence against dangerous electrical faults occurring, power earthing systems must be inspected and tested at regular intervals to ensure they remain effective and meet the following requirements.

- BS 7430:2015: Code of Practice for Protective Earthing of Electrical Installations.

- BS EN 50522: 2022: Earthing of Power Installations Exceeding 1kV AC.

- ENA Technical Specification 41-24: Guidelines for the design, installation, testing and maintenance of main earthing systems in substations.

- Health Technical Memorandum 06-0: Electrical services supply and distribution.

- SFG20: Building Maintenance Standard, HOSPITALS AND HEALTHCARE PREMISES – Health Technical Memorandum requirements.

Inspection Schedule

- Visual inspection annually

- Full test and maintenance of system to be carried out at a period not exceeding 5 years

- Only trained and competent power earthing engineers should perform these tests

A failed power earthing system can have serious consequences, including:

- Electric shock: People can be electrocuted if the power earthing system is ill maintained or insufficient (not fit for the purpose intended).

- Fires: Sparks and arcs caused by an earth fault can lead to fires.

- Equipment damage: Without adequate grounding, equipment can experience voltage surges and spikes that can cause catastrophic damage.

- Loss of data: A failed earthing system can lead to the loss of mission-critical data.

- Risk to life: A substandard or inadequate power earthing system has the potential to cause life threatening situations.

- Safety risks: Faults that aren’t isolated quickly can create dangerous conditions for people and infrastructure.

- Increased costs: Equipment may need to be replaced due to damage.

Benefits of Power Earthing Testing

- Enhanced Safety: Prevent potential hazards caused by electrical faults with reliable Power Earthing systems.

- Operational Reliability: Reduce unexpected downtimes and protect sensitive equipment.

- Compliance Assurance: Meet industry and regulatory standards with certified testing.

- Proactive Maintenance: Identify and resolve issues before they become dangerous and potentially fatal.